Please scroll down

New corporate video

Gases for tomorrow

In our new corporate video, you can learn more about our divisions Energy, Air Gases, Hydrogen and Trading - with impressive pictures and authentic moments.

Press

MPREIS Hydrogen GmbH

Tyczka Hydrogen acquires MPREIS Hydrogen GmbH in Völs

Press

Two new H₂ refuelling stations

Tyczka Hydrogen Acquires Two Hydrogen Refuelling Stations from MorGen Mobility

Industrial gas of today, energy source of tomorrow

Towards a greener energy industry with hydrogen

Hydrogen has been used in many industrial applications for over 100 years. As a supplier of both, industrial gases and the energy carrier liquefied petroleum gas, Tyczka is helping to unlock the full potential of hydrogen and make its contribution to the decarbonisation of industry, mobility and heating. The suitability of green hydrogen as an emission-free energy carrier for the energy transition is now undisputed and is being introduced in numerous sectors, such as heavy goods transport, rail transport or in industry for material utilisation or process heat generation.

As a hydrogen supplier, we are personally at your side for your application.

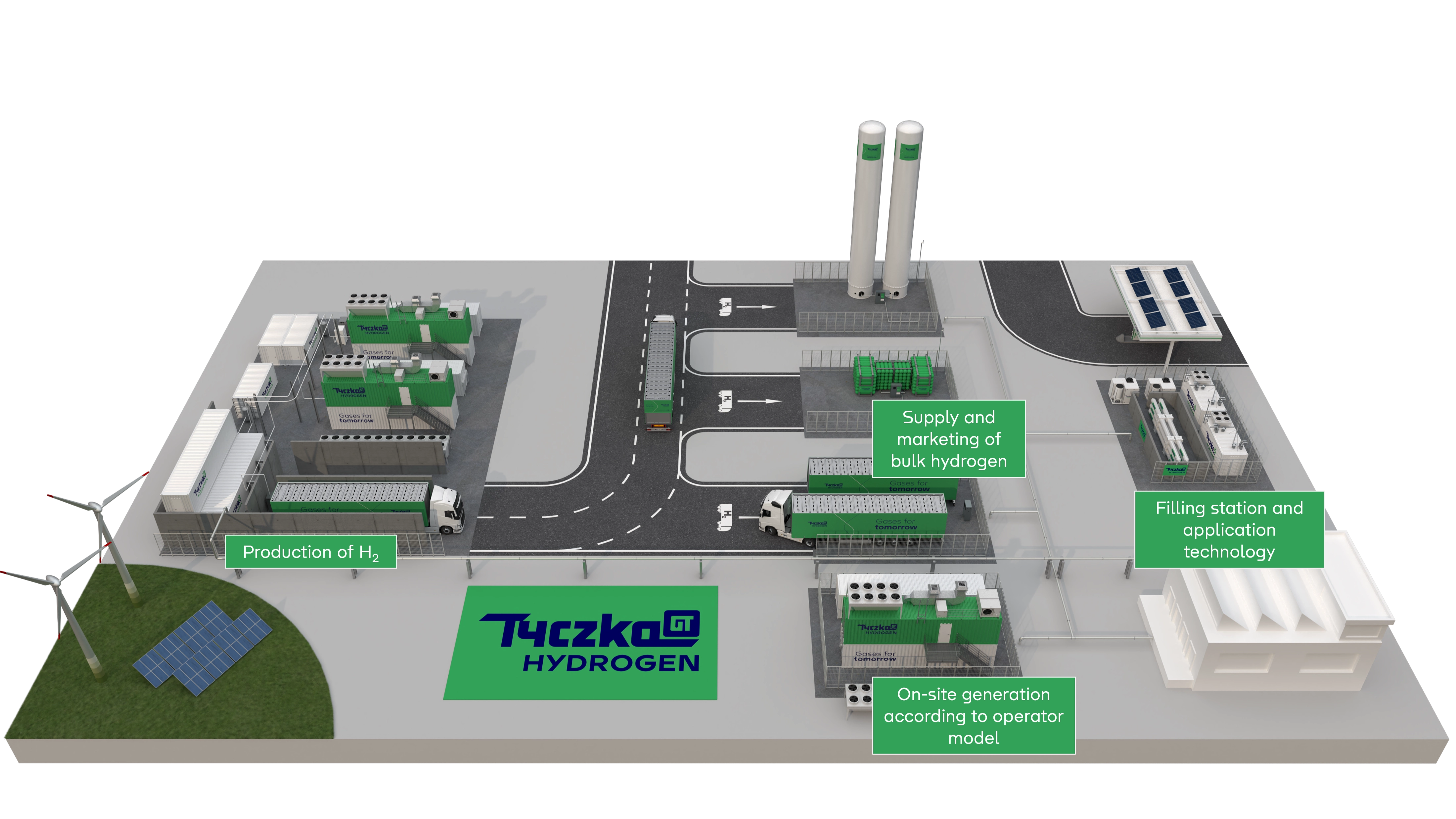

Tyczka as a partner for the entire hydrogen value chain

We are a supplier of hydrogen and cover the entire value chain from production, compression and filling, transport and logistics to filling and application technology.

Hydrogen production

- Green hydrogen with electrolysis from renewable energies

- Various H2 sources for high availability

Compression and filling

- Many years of operating experience with industrial gas systems

- Expertise in plant engineering

- Highest quality standards

Transport and logistics

- Over 100 years of experience in supplying customers with industrial and energy gases

- Established logistics network

- Reliable delivery

Filling and application technology

- Storage and application solutions for our customers, including H2 refuelling stations

Individual purposes of application

for your hydrogen requirements

The Tyczka Hydrogen quality promise

- Customised solutions from a single source - for your individual needs.

- Security of supply thanks to our broad source network.

- Safety in handling hydrogen thanks to our many years of expertise in the field of industrial gases.

- All-round service for you: covering the entire hydrogen value chain - from production and transport to refuelling.

- Over 100 years of Tyczka - 100 % reliability: The success story of our traditional family business stands for continuity and stability.

Hydrogen is the connecting element of a cross-sector energy transition. We will accelerate this transformation with hydrogen from Tyczka. Hydrogen is happening now!

Exhibitions and Events

with Tyczka Hydrogen

Meet us soon

You can find Tyczka Hydrogen at relevant industry events to connect, exchange experiences, discuss solutions for current problems and receive impulses.

Get in touch with us

Our experts will find the right solution for your hydrogen requirements.

FAQ about hydrogen

Hydrogen plays a major role in the energy transition, as surplus energy can be used to produce hydrogen on sunny and windy days. The hydrogen is then available for use in mobility and industry independently of the sun and wind. Hydrogen is easier to store than electricity and therefore offers an alternative storage option for electricity from renewable energies. In addition, green hydrogen can be used to realise emission-free mobility and emission-reduced industry (e.g. steel).

Hydrogen can be produced in different ways. At present, hydrogen is primarily obtained from fossil fuels, mainly by steam reforming from natural gas. Green hydrogen is produced by electrolysis using electricity from renewable energies. In this process, water is broken down into hydrogen and oxygen using electricity. By using renewable energies to generate electricity, hydrogen can be produced completely emission-free. There are also other types of production, each of which is assigned a different colour (see next question).

Hydrogen is a colourless gas. The different colours mentioned in connection with hydrogen refer to the way it is produced. The hydrogen itself does not differ in colour apart from the possible presence of trace impurities.

Green hydrogen

Green hydrogen is produced by electrolysis using electricity from renewable energy sources. From today's perspective, this path is the most sustainable and plays a central role for the hydrogen sector at Tyczka.

Turqouise hydrogen

Turquoise hydrogen is produced by what is known as methane pyrolysis. In this process, methane is split into hydrogen and carbon at high temperatures. Here, too, electricity is required to heat the methane to a temperature of over 1,000 °C. As the carbon is present as a solid, turquoise hydrogen is considered CO2 neutral if the electricity required to split methane comes from renewable energies.

Grey hydrogen

Grey hydrogen is produced by steam reforming from fossil fuels (usually natural gas). Hydrogen, carbon monoxide and carbon dioxide are produced from water and natural gas. Most of the hydrogen used today is grey hydrogen.

Blue hydrogen

Blue hydrogen is grey hydrogen in which the carbon dioxide produced is captured and stored. Possible storage locations are depleted oil and gas fields or in natural storage facilities under the sea. However, not all of the carbon dioxide can be captured, meaning that blue hydrogen is not completely CO2 neutral.

Other colours

There is also yellow hydrogen (electrolysis with electricity from the grid electricity mix), orange hydrogen (gasification/fermentation of biomass, steam reforming of biogas or electrolysis with electricity from waste-to-energy plants), red (electrolysis with nuclear power), white (natural hydrogen deposits) and brown hydrogen (coal gasification). Hydrogen produced as a by-product in industry is also sometimes referred to as brown hydrogen. An official standardised definition is not yet available (as of August 2021).

Industry

Hydrogen has been used in industry in a variety of ways since the early 20th century. In refineries, hydrogen is used to desulphurise oil products and to convert long-chain hydrocarbons into short-chain hydrocarbons. 55% of the hydrogen produced globally is used to produce ammonia, e.g. for fertilisers. The production of methanol, e.g. for fuels, accounts for 10% of the hydrogen produced. Hydrogen can also be used in the food industry to harden fats, e.g. for margarine, in the production of plastics, in the alloying of metals and as a protective gas. By directly reducing iron ore with hydrogen, steel can be produced without carbon dioxide emissions.

Mobility

Almost all means of transport can be powered by hydrogen. An electric motor is supplied with electricity via a hydrogen fuel cell and moves the vehicle. There are forklift trucks, cars, buses, lorries and trains that run on hydrogen. Hydrogen has been used as a fuel in rockets since the 1960s.

Buildings/ Heat

In addition to electricity, a fuel cell also produces heat, which can be used to heat buildings. This combined heat and power increases the efficiency of the fuel cell.

Research and development

As a reliable hydrogen supplier, Tyczka offers customised solutions for research and development: from cavern leak tests and their initial filling to the provision of hydrogen for engine and fuel cell test benches. Tyczka also uses its expertise to support the development of synthetic fuels, thereby actively promoting the transition to a sustainable energy future.

Hydrogen can be available in different purity levels. This means that the proportions of the remaining gases vary. The hydrogen purity is either stated as a percentage or abbreviated with a combination of numbers, for example 3.7. The number before the dot stands for the number of nines, the number after the dot for the number that comes after the nines.

Commercially available hydrogen is 3.0, i.e. 99.9 % by volume. For higher purity requirements, e.g. in the semiconductor industry, hydrogen 5.0 (99.999 % by volume) is used.

The exact composition of the remaining gases can also be decisive. For example, the proportions of certain impurities must not exceed certain limits for the hydrogen to be used in fuel cells.

Availability

Hydrogen can be produced from water using electricity. This is done using so-called electrolysers, a technology that has been known and used since the beginning of the industrial revolution. Hydrogen can also be stored efficiently in large quantities and over long periods of time. Salt caverns, for example, are used for this purpose. Stored hydrogen can be used when the sun is not shining, the wind is not blowing and there is no electricity available from other renewable energy sources.

Production method

Hydrogen can be produced using surplus electricity from renewable energy sources. The electricity is therefore utilised when it is available, and the energy can be used when it is needed. Hydrogen is therefore a second, flexible energy source alongside electricity, which also utilises a different infrastructure and thus spreads the challenges of the energy transition over another shoulder.

Comparison with a combustion engine

Hydrogen vehicles with fuel cells have the great advantage over a vehicle with an internal combustion engine of not emitting any local greenhouse gas emissions or other pollutants. With green hydrogen, there are also no emissions during production. In addition, fuel cell vehicles are electric vehicles and therefore quieter than those with an internal combustion engine, and the lower number of moving parts means less wear and tear. Fuel cells are also more efficient than petrol engines. The efficiency of the fuel cell is around 50 %.

Comparison battery vehicle

The refuelling process for hydrogen in cars is comparable to that for petrol or diesel and takes 3-5 minutes. In addition, a hydrogen tank, especially in lorries, is lighter than a battery with a corresponding range. This increases the possible payload of the truck. In addition, less problematic raw materials (e.g. lithium) are used in fuel cells.

Flexible applicability

Hydrogen can also be used in applications without a connection to the electricity or gas grid. Hydrogen can also supply remote regions with the help of trailers (truck transport) or gas cylinders. One application example is emergency power supply systems for radio masts for critical infrastructures.

Transport

There are fewer losses when transporting hydrogen through a pipeline than when transporting electricity. It is also possible to use the existing natural gas network to transport hydrogen. See German hydrogen core network: Federal Network Agency - Hydrogen core network Bundesnetzagentur - Wasserstoff-Kernnetz

Storage

Hydrogen can be stored in existing natural gas caverns with large storage capacities. The gravimetric energy density of hydrogen, i.e. the ratio of energy to weight, is very high. A lot of energy can be stored with a small amount of hydrogen.

Hydrogen buses produce no pollutants locally and are quieter than buses with combustion engines. Compared to the battery-electric alternative, they also have longer ranges and can be used well in multi-shift operation and on hilly terrain. Hydrogen can therefore improve the quality of life in cities and rural areas.

In the heavy-duty sector (trucks), hydrogen fuel cells enable long ranges with a payload comparable to that of a diesel truck and shorter refuelling times than battery electric vehicles. The high level of flexibility is crucial for many logistics companies.

Forklifts that are powered by hydrogen fuel cells have no local emissions and can therefore also be used indoors. Short refuelling times mean that the forklifts can be used continuously in multi-shift operations.

Trains, for example in regional transport, can also use hydrogen on routes that are not equipped with an overhead line. Due to the low capacity utilisation, trains there are typically operated with diesel fuel. Hydrogen offers a climate-friendly, flexible alternative with comparable performance.

Hydrogen fuel cell cars enable locally emission-free driving that comes close to driving a car with an internal combustion engine in terms of range and performance.

Hydrogen can be transported by trucks in pressurised gas containers. For longer distances, hydrogen can also be transported in liquid form by trucks or ships. Very large quantities of hydrogen can also be transported efficiently in a pipeline. Here it is possible to convert existing natural gas pipelines.

The calorific value of hydrogen is 33,000 kWh per tonne. This means that the combustion of one tonne of hydrogen releases 33,000 kWh of heat. If you convert the energy in hydrogen into electricity using a fuel cell, you get 16,500 kWh of electricity per tonne of hydrogenat an efficiency of 50%. This could light a 60W light bulb for almost 31 years or run a vacuum cleaner with 1.5 kW continuously for a year and 3 months.

Hydrogen is not fire-promoting, toxic, radioactive, foul-smelling, corrosive, carcinogenic or hazardous to water. Hydrogen is not a greenhouse gas and does not contribute to global warming.

The pressurised hydrogen tanks are subject to the highest safety criteria. In the rare cases in which a hydrogen tank leaks, the hydrogen volatilises very quickly due to its low density. A hydrogen flame also burns quickly, straight upwards and with little heat radiation.

Hydrogen is therefore no more dangerous than petrol if it is used with the necessary care.

Hydrogen and fuel cell technology are currently competing with technologies and energy sources that have been mature for decades. Further economies of scale and mass production effects are therefore required to achieve the necessary further cost reductions. With increasing quantities, prices are expected to fall further, so that more companies and private individuals will decide in favour of purchasing fuel cell vehicles. In addition, changes in the regulatory framework, particularly regarding the assessment of CO2 emissions, will influence competitiveness.

Another problem is the infrastructure, which is often described as a chicken-and-egg problem: There are only a few refuelling stations that can supply vehicles with hydrogen. As a result, few people decide to purchase such vehicles. The fewer fuel cell vehicles there are, the lower the demand. Due to the low demand, hydrogen refuelling stations are currently less profitable than they would be at full capacity. The industry and politicians have recognised this problem and are working on creating a basic infrastructure in Germany and Europe as part of overarching collaborations.

For a quick overview, we recommend the following website:

https://h2.live